Clutch Components

Product Overview

High-quality clutch components are an essential part of automatic transmissions. Because of its net-shape capability, powdered metal is a preferred method of manufacturing for many backing plates, pressure plates, clutch hubs, and one-way clutch components. With low tooling costs, minimal waste, and tight tolerance capability, customers can achieve savings through the use of powdered metal for these applications.

One-way clutches are used to engage and disengage gear sets that transmit torque in the transmission. Most one-way clutches consist of an inner and outer race, and a mechanism between those components that locks rotation in the desired direction.

Keystone supplies many different parts for use in various one-way clutch designs, including sprag clutches, roller clutches, rocker clutches, and mechanical diodes. In addition to manufacturing powdered metal clutch components, Keystone also assembles many one-way clutches for customers.

| Applications | Specifications |

|---|---|

|

|

Secondary operations include machining, grinding, sanding, heat treatment, tumbling (for burr removal), and assembly of one-way clutches.

Give us a call to discuss how we can help improve your clutch components.

One-Way Clutch Assembly

The assembly process at Keystone combines our extensive experience in powdered metal manufacturing, our expertise in automation engineering, our drive to advance manufacturing technology, and our world-class customer support. Through this depth of understanding and motivation, we have designed and built automated assembly machines to assemble one-way clutches to meet customer specifications.

Assembling our one-way clutch components is a highly automated process, using multi-station equipment to assemble and 100% test each clutch to ensure proper assembly and performance.

Read the story behind our one-way clutch assembly equipment, which illustrates our leading-edge technology and the capabilities of our people. This is a prime example of our commitment to providing maximum value for customers.

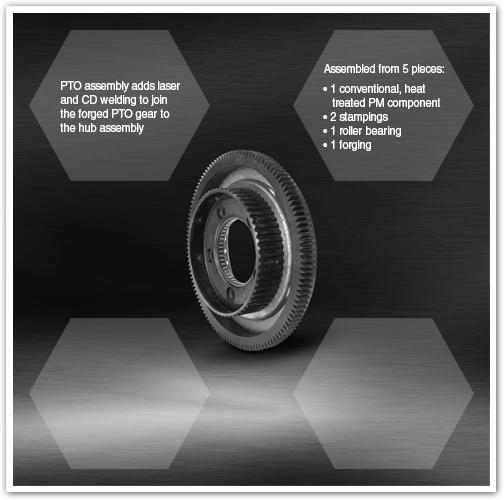

Coast Clutch Hub for Power Take-Off (PTO) Assembly

Keystone also assembles the PTO (Power Take-Off) version of the coast clutch hub built into medium-duty work trucks for powering auxiliary accessories. To attach the forged PTO gear to the rest of the clutch hub, Keystone incorporated two welding operations (laser and capacitor discharge) and two additional components into the assembly process.

We work closely with our suppliers to verify that the quality of their parts and services matches the quality of parts we manufacture, ensuring that the complete assembly meets customer specifications.